- 日本語

- ENGLISH

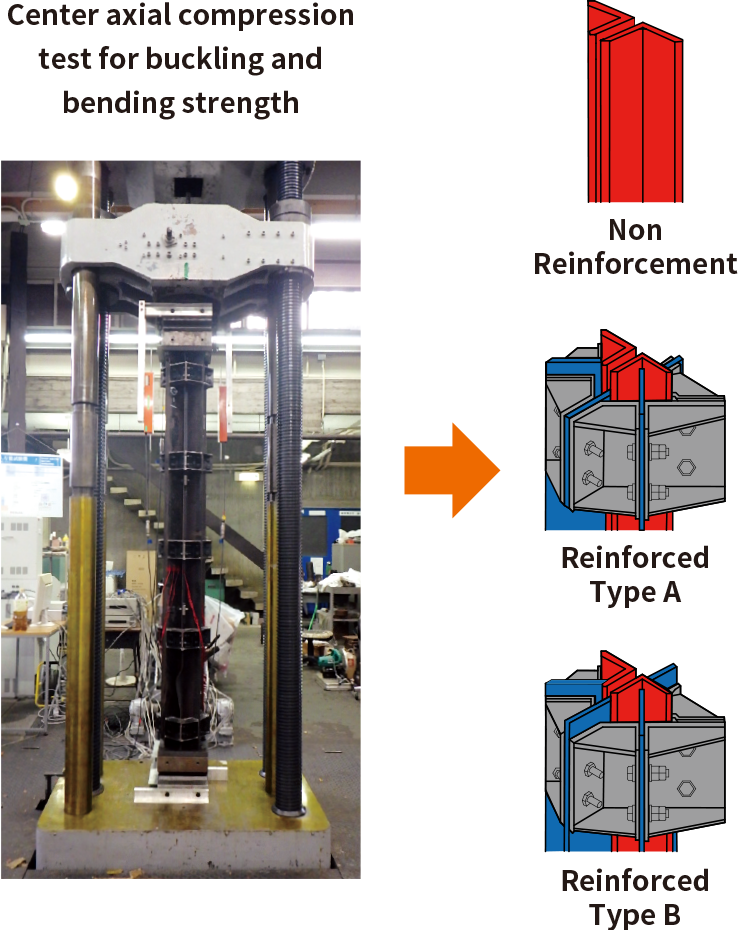

An innovative, simple, and safe construction method for reinforcing angle steel structures against buckling, as well as for mounting facilities and accessories on the structures, without performing additional metal processing work.

An innovative, simple, and safe construction method for reinforcing angle steel structures against buckling, as well as for mounting facilities and accessories on the structures, without performing additional metal processing work.

Drilling through and welding to an existing steel structure for

reinforcement has a negative impact on its strength.

IMB does not require any drilling and welding, due to our unique products

made with patented bundling technology, which prevents peeling of the

plated layer of the steel structure during installation work, and reduces

the potential for corrosion.

No drilling and no welding also provides another useful benefit,

enabling easy and repeated changes of fixing places (points)

after the initial installation.

Neither large machinery, tools nor scaffolding are required because

drilling and welding are not needed.

Just simple tools suffice for fastening the bolts and nuts for

attaching the metal fittings, which greatly reduces the construction

period, saving on the total cost of ownership.

When conducting aerial work, easy installation without equipment and

tools is a crucial factor for significantly improving safety.

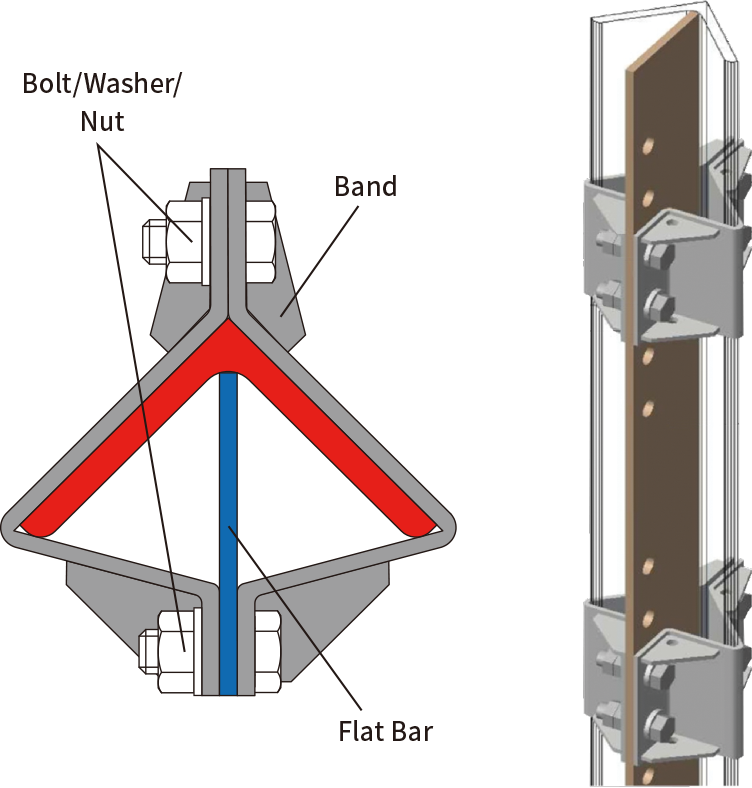

The IMB method consists of the "flat bar", steel band", and "bolt/washer/nut". This unique method enables reinforcement, and provides mounting facilities on an angle steel structure without drilling and welding. Therefore, the original specifications and strength of the base metal can be maintained.

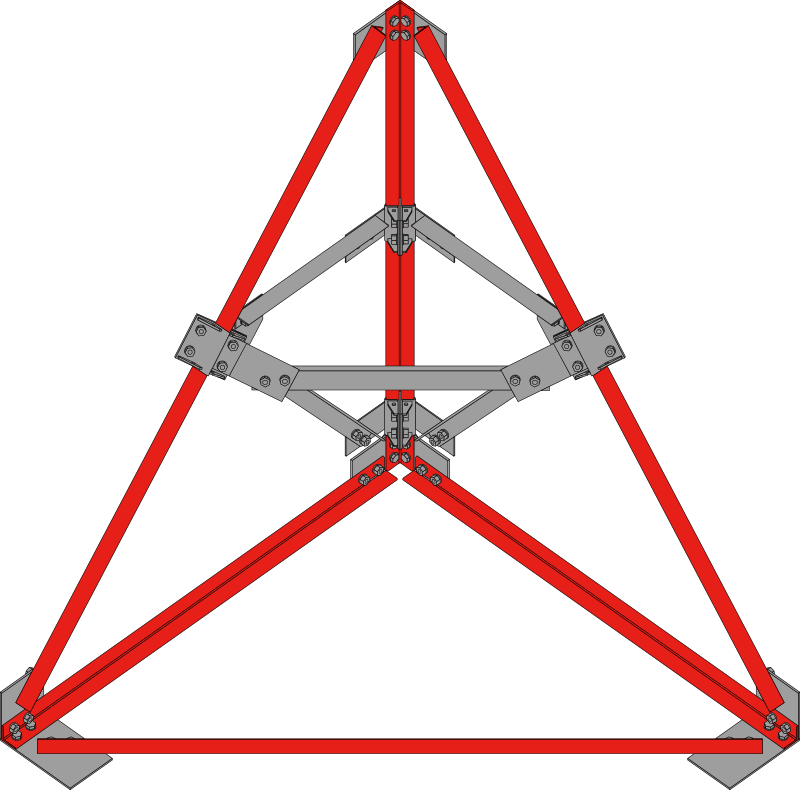

The effect of reinforcement by IMB method can be further enhanced with the introduction of the truss structure reinforcing materials.

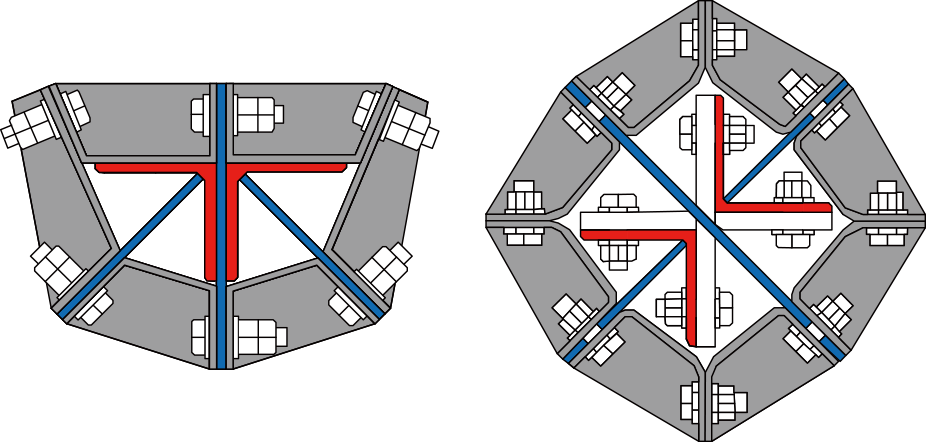

The IMB method can be made applicable to the reinforcement of single L-shaped angle steel, as well as to various combinations of angle steel materials, and provides a higher degree of strength.

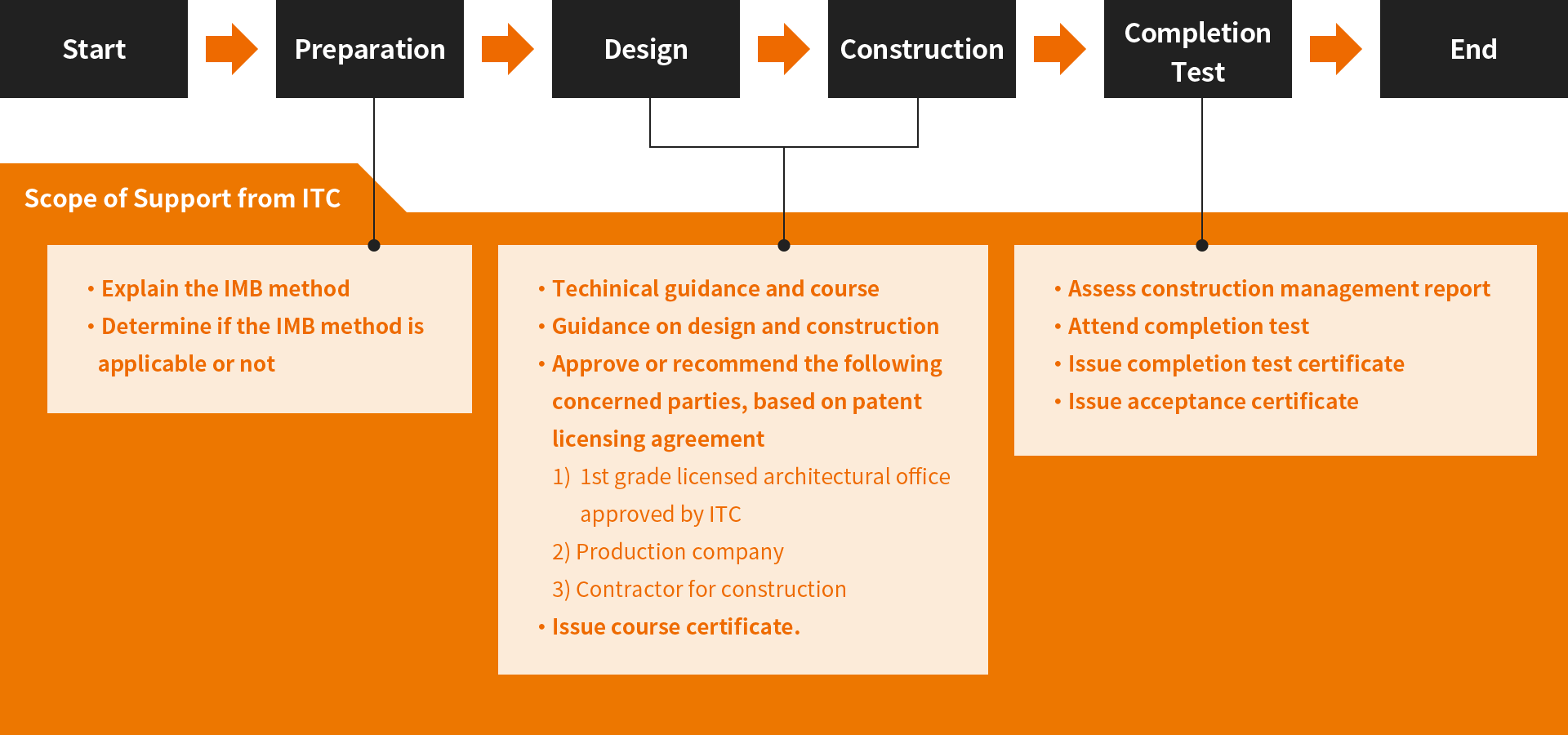

The inquiry form from hereINQUIRY FORM

Applied to reinforcing angle steel

structures, such as towers,

factories, plants and

gymnasiums, etc.

Enables simple and quick installation

of various facilities and accessories,

such as lightning rods and antenna

supports, without drilling and

welding on towers.

The inquiry form from hereINQUIRY FORM

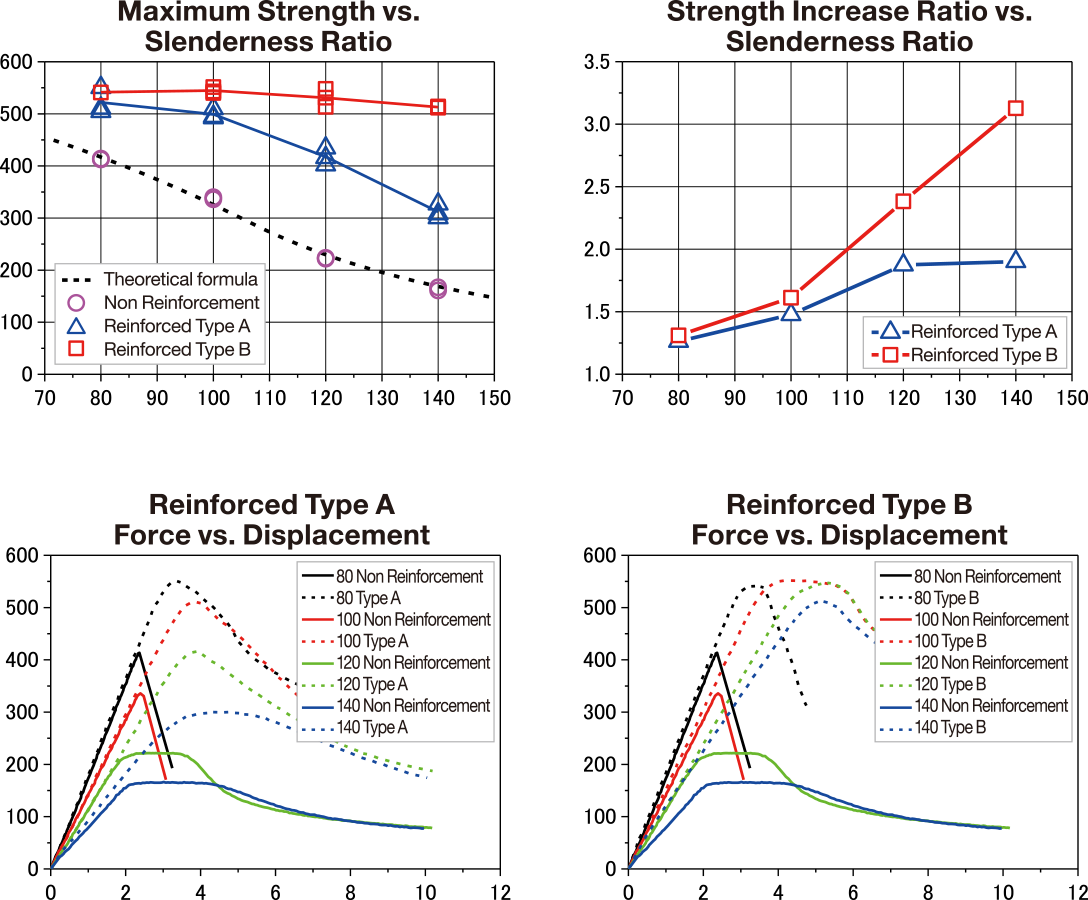

Joint experimentation and research conducted with the Nihon University College of Industrial Technology recorded a remarkable increment of strength of between 1.3 times (1.3x) and 3.1 times (3.1x) when compared with non-reinforced materials.

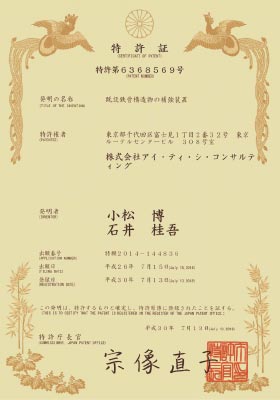

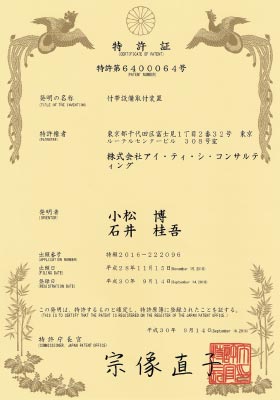

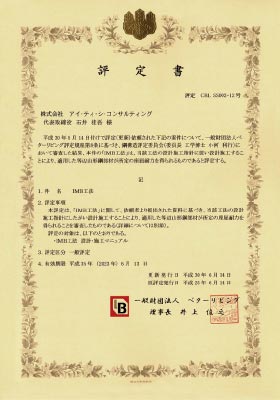

The IMB method has been granted four patents for various types and usage of angle steel. In addition, the advisory panel under Japan Accreditation Board consisting of experts in the field of steel structural design has issued a performance certificate for industrial application based on Japan’s Building Act. Another patent application has been filed in Japan, and we are going to file PCT international application based on that.

Accreditation Certificate No. CBL SS002-12 (Valid until June 13, 2023)

* In accordance with Japan's Building Standards Act, Clause 68, Article 26.

The inquiry form from hereINQUIRY FORM